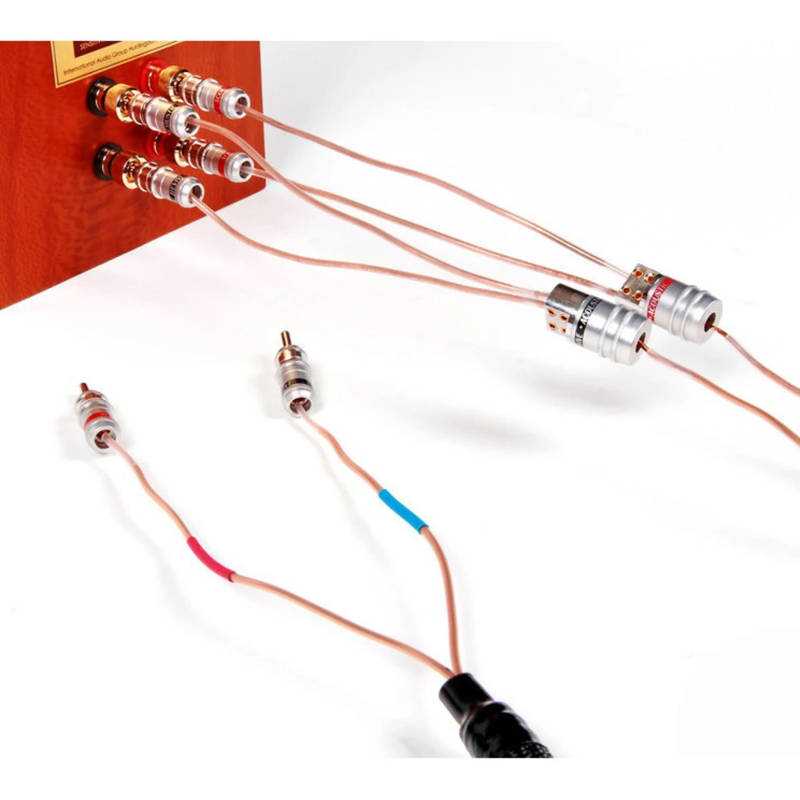

Currently, many speakers use bi-wire compatible input terminals. This is to prevent the counter electromotive force generated from the low frequency side due to the amplitude movement of the woofer from flowing to the high frequency side and deteriorating the sound quality. Originally, two power amplifiers are used for the low frequency side and the high frequency. The correct connection method is to drive the side separately by bi-amp drive, or to connect the amplifier side to the low-frequency side and high-frequency side separately with two sets of speaker cables, but this fact is unexpectedly known. It seems that there are many things that are not there. Not knowing this fact, even specialized magazines have recommended connecting the high-frequency side and the low-frequency side as a crosspiece, and some cable makers have released expensive jumper wires that are completely meaningless. That's why. For bi-wire compatible speakers, it is correct to eliminate jumpers and connect two sets of speaker cables separately for the low-frequency side and high-frequency side, and the original speaker performance is exhibited. However, speaker cables have become more expensive in recent years, and those who cannot afford to buy two sets of speaker cables, or who have only one set of speaker terminals on the amplifier side, connect two sets of thick speaker cables. Some people can't do that. The bi-wire adapter BWA-4 solves this problem. By cutting off the tip of the speaker cable you are currently using by about 30 cm and reconnecting it to the low frequency side and high frequency side separately from BWA-4, the counter electromotive force prevention effect is very close to pure by-wire connection. You can get it.

Back electromotive force reduction data by "BWA-4"

■ Back electromotive force reduction data by "BWA-4"

50Hz, 100Hz, 200Hz tone burst signals were reproduced, and the back electromotive force flowing into the high frequency side terminal was measured. A uses bi-wire adapter BWA-4

B is attached Jumper plate used

C uses high-grade jumper wire * The amount of back electromotive force is almost the same between the attached jumper plate and high-grade jumper wire, but dramatically with "BWA-4" The back electromotive force is reduced.

Ultimate conduction performance that does not cause deterioration of sound quality!

In order not to cause deterioration of sound quality by inserting an adapter in the middle of the speaker cable, BWA-4 takes measures to improve the continuity performance to the utmost limit. The material is lead-less brass with high conductivity, rhodium-plated, gold-plated double screw that does not deteriorate conductivity such as soldering and crimping, and secure cable fixing method, and ultra-low temperature treatment at minus 196 ° C improves conductivity. We are improving.

Insulation tube is also included

BWA-4 comes with an insulating tube to prevent the + and-terminals from touching and short-circuiting. If the + -terminals are too close to each other and are likely to come into contact with each other, be sure to cover them with an insulating tube.

Vibration control structure that improves sound quality!

By combining the 2017S aviation level aluminum alloy cap, BWA-4 exerts a damping effect due to the combination of dissimilar metals with the brass of the main body. This vibration damping structure makes it possible to quickly attenuate the vibration transmitted from the speaker terminals and speaker cables and further improve the sound quality.